Views: 20 Author: Site Editor Publish Time: 2024-07-03 Origin: Site

Originally, EL testing has evolved to form one of the key components of quality control for photovoltaic (PV) panels. Through the use of the electroluminescence mechanism existing in crystalline silicon, EL testing is a thorough and non-invasive technique for identifying numerous kinds of defects in solar panel configurations for optimal efficiency and reliability. This innovative diagnostic equipment produces near-infrared image of crystalline silicon through the help of a high resolution infrared camera which gives good image of PV cells with defects.

The main application of the photovoltaic panel EL detector is to detect defects with accuracy and speed. The common defects that can be detected include:

- Gate breaks

- Cracks

- Fragmentation

- Improper brazing

- Sintered mesh defects

- Black cores

- Letter boxing

- Blending issues

- Low-efficiency chips

- Edge etching

- Potential-induced degradation (PID)

- Attenuation

- Hot spot attenuation

If not identified, these defects greatly threaten the long term reliability and efficiency of PV panels and therefore solar power systems.

Advantages of the EL Detector:

1. High Accuracy and Efficiency: The output of the EL detector contains information about the time and place of the defect and the type of defect, which helps quickly make a decision to eliminate the defect.

2. Non-Destructive Testing: EL testing does not harm the PV panels in any way, maintains the physical well-being and functionality of the PV panel while providing maximum diagnostic reports.

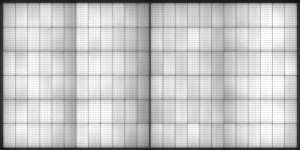

Qualified EL test images are as follows:

The knowledge of the most frequently observed defects using EL imaging will help to modify production processes and, consequently, improve the properties of the panels. Understanding these defects, the causes, impacts and control measures are provided in details below.

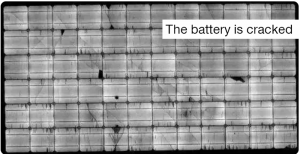

- Causes: They may appear as a result of an external force applied when welding or when the material is being moved around, low pre-heating followed by rapid heating or vice versa and lastly, high temperatures during welding.

- Module Effect: Cracks affect power control and cause hot spots, creating low performance risks and possible module burnout.

- Preventive Measures: Control external disturbances during processing, heat panels before welding, and achieve proper welding temperature not to cause thermal stress.

- EL Imaging Features: An x mark drawn between the grid lines and crossed black lines along the principal grid line means the cells are separated.

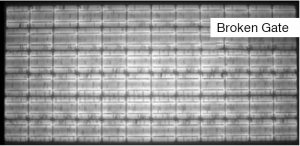

- Causes: Inappropriate display printing, screen printing, silicon slicing, and manufacturing defects.

- Module Effect: Decline in efficiency when it comes to collection of the present owing to the overall decreases in performance.

- Preventive Measures: A comprehensive approach must be adopted to reduce gate breakage by utlizing the right settings for screen printing, correctly choosing every screen material, put in place standard operating procedures and incorporate monitorage for real time control.

- EL Imaging Features: Rings of different density radiating from the middle of the circles with some segments of the picture looking pitch black and non-glowing.

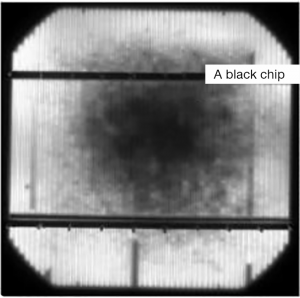

- Causes: They include contamination of silicon rod during the process of crystallization, non-optimized matching of the temperature gradients and intense thermal stress on the rods used during fabrication.

- Component Impact: Thermal destruction and decreasing of the power during usage, manifested as step-formed IV characteristic curve during the experiment.

- Preventive Measures: Coagulation coefficient and oxygen solubility in silicon rods should be controlled to avoid contamination and to achieve an optimal match of the temperature gradient.

- EL Imaging Characteristics: Black pixel portions at exact locations in certain types of modules.

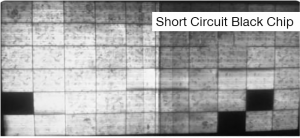

- Causes: Short circuit between electrodes; reverse welding; poorly made connections; low efficiency, cells. These also result from misuse of N-type wafers and absence of PN junctions.

- Module Effect: Dependently on the angle of light incidence, the fill factor and the output power decreases while the overall module efficiency is affected.

- Preventive Measures: That is why proper soldering should be done, check junction box diode connections, and do not use poor quality silicon wafers to support module integrity.

EL testing is indispensable in the solar power industry, offering several key benefits that enhance the overall quality and reliability of PV panels:

1. Enhanced Photoelectric Conversion Efficiency: Through use of EL testing, defects are detected and corrected early hence help in keeping the efficiency of the solar panels at the optimal level thus enhancing energy conversion efficiency.

2. Cost Reduction: Early defect recognition minimizes future maintenance and replacement expenses of solar energy systems; thus, it increases the sustainability of solar energy systems.

3. Promotion of Renewable Energy: Strengthening, reinforcement, and optimization of solar power systems contribute to the general cause of renewably powered technology.

4.Improved Stability and Reliability: Continuous EL testing ensures that the solar power systems are dependable during their life cycle and the systems deliver constant energy output and not a point of failure.

The photovoltaic panel EL detector is one that is used to ensure high quality and performance of the solar panel. By operating through the electroluminescence principle it offers non-invasive, accurate technique for detecting a whole spectrum of defects that can affect the functionality and reliability of the solar power plants. Not only does it affect cost reduction and optimization of energy conversion efficiency; it is also instrumental in furthering the promotion of renewable energy. Given the ever increasing focus on clean and renewable form of energy such as solar energy, the EL testing plays important role in meeting reliability and efficiency requirements of solar PV panels.

What Approach Should One Take To Select The Proper Capacity For Solar Energy Storage Batteries?

Is It Worth Importing PV Panels From China And Selling Them In Your Country?

How to Calculate Solar System ROI and Optimize Long-Term Returns?

PV industry loses $6.5 billion: reinvention or obsolescence?

Solar Carports in Europe: Costs, Installation, and Tax Incentives

What Is the Better Method for Connecting Solar Panels Either Series Way or Parallel?